| Quantity | Unit Price | You Save |

|---|---|---|

| 3 or more | R 1,326.26 | 1.54 % |

| 6 or more | R 1,296.34 | 3.76 % |

| 12 or more | R 1,271.41 | 5.61 % |

- Stock: 2

- Model: TCAC048-1

- Weight: 0.26kg

- Dimensions: 72.00mm x 70.00mm x 98.00mm

- SKU: TCAC048-1

- UPC: 6009515828448

Annular Cutter: Ø 48 mm

One

way to avoid dimpling and deburring while making holes in tube and pipe is to use

annular cutters. Because annular cutters are hollow on the inside, there is no dead-zone

resistance to overcome.

One

way to avoid dimpling and deburring while making holes in tube and pipe is to use

annular cutters. Because annular cutters are hollow on the inside, there is no dead-zone

resistance to overcome.

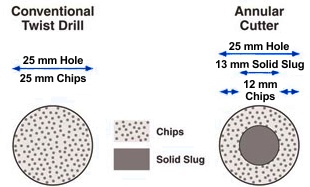

Using a twist drill to make holes in pipe or tubing can prompt concerns about the hole roundness, location accuracy, hole finish, chip extraction, burrs, and drilling duration.

The focal point of these concerns is the twist drill's most noticeable feature; its point. This is not really a point at all, but the tangent line where two cutting angles intersect at the web of the drill, or the so-called 'dead zone.' This dead zone causes the surface speed of the cutting edges to drop to zero.

The lower surface speed reduces cutting efficiency and requires increased thrust, or feed pressure, for the cutting edges to push through the material.

Compared to traditional tooling (twist drills, etc.) annular cutters can multiply your cutting speed by up to 3 times while getting a longer tool life, a more accurate hole, a better finish, with no burrs. The cutting edges distribute the cutting load evenly, thus making it faster cutting.

Annular

cutters convert a smaller area to chips, requiring less horsepower and thrust. This

feature provides longer tool life and less chatter. The slug also offers a higher

scrap value than loose chips and shavings.

Annular

cutters convert a smaller area to chips, requiring less horsepower and thrust. This

feature provides longer tool life and less chatter. The slug also offers a higher

scrap value than loose chips and shavings.

Definition - Annular

'Ring-shaped' or 'forming a ring'. From the latin word annulus

General Drilling Tips

-

Always

use coolant when drilling. This will prolong the cutter’s life and offer a better

finish.

Always

use coolant when drilling. This will prolong the cutter’s life and offer a better

finish. - Slower feed rates will not add life to your cutter but actually reduce the cutter's life. Use firm steady feed pressure throughout cut. This is the Number #1 cause of broken or prematurely dull cutters

- Clean the cutter. Always make sure to clear all chips from your cutter before starting the next hole.

- Know the material characteristics. For harder materials other cutting options should be investigated

- Make sure support system for drill arbor is in place and not worn out. If using on a drill press, a support system must be used.

- Take care that the surface below the magnetic drill is clean and that the work piece is securely attached. Uneven or large build-up of debris and shavings can cause drill slippage. Material being cut should be at least 8mm thick.

- Painted surfaces pose possible slippage if paint build-up does not allow magnet to hold securely.

- When slug ejection becomes unreliable or tool resists cutting, replace your cutter or send in for re-sharpening.

- Always observe standard and specific safety instructions.

- For best performance always maintain your drill as instructed in your tool operator's manual.

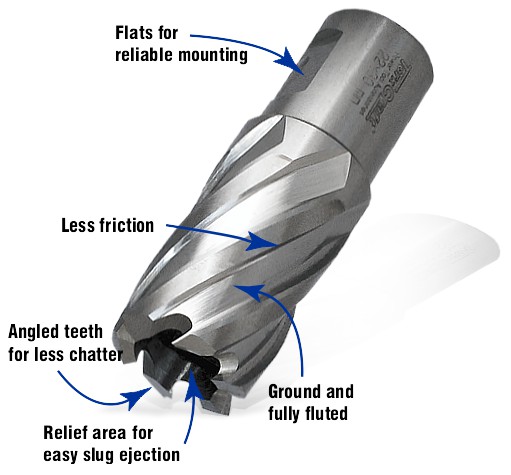

Features and Benefits

- Perfect stable start

- Conical surface inside

- Precise centre pilot fitting

- Ground clamp surface

- Faster, because every tooth cuts

- More accurate

- Greater drill depth

- Stronger, therefore less fragile

- Guaranteed slug ejection

At a glance

- Annular Cutters drill a burr-free finished hole by cutting only the material around the periphery of the hole. This forms a solid slug which will fall out.

- Less time and energy are consumed per hole

- Faster feed rates are achieved with more cutting teeth and less tool wear

- Lighter, less powerful drilling equipment can be used

- Able to drill holes which are difficult or impossible to do accurately with conventional twist drill tooling - with no pre-drilling or step drilling required.

| consider safety for your health and the people around you | |||

General safety suggestions:It is advisable to always have the following items nearby and in a good condition

|

|||

|

|

|

|

|

|

Wear Gloves

|

Eye Protection

|

Hearing Protection

|

Safety Shoes

|